Introduction

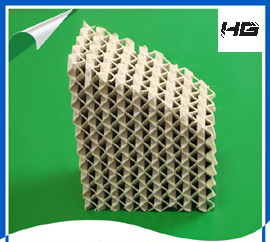

Ceramic Structured Packing consists of many packing units of similar geometric design. Corrugated sheets placed in parallel formcylindrical units called corrugated tower packing. These are a form of highly efficient packing with separating efficiency several times higher than that of loose packing. They have the quality of low-pressure drop, increased operating elasticity, minimum amplifying effect, and maximum liquid treatment compared to loose tower packing.

Technical specifications

| Model: | Ceramic Structured Packing | ||||||||

| Shape: | Ripple | ||||||||

| Color: | White | ||||||||

| Chemical composition | |||||||||

| SiO2 | Fe2O3 | CaO | Al2O3 | MgO | Other | ||||

| ≥72% | ≤0.5% | ≤1.0% | ≥23% | ≤1.0% | 2% | ||||

| Physical property | |||||||||

| Index | Value | ||||||||

| Specific gravity(g/cm3) | 2.5 | ||||||||

| Water absorption(wt%) | ≤0.5 | ||||||||

| Acid resistance(wt%) | ≥99.5 | ||||||||

| Loss in burn(wt%) | ≤5.0 | ||||||||

| Max. operating Temp.(Degree C) | 800 | ||||||||

| Crush strength(Mpa) | ≥130 | ||||||||

| Mohs Hardness(Scale) | ≥7 | ||||||||

| Geometric characteristic | |||||||||

| Spec. | Specific surface(m2/m3) | Bulk density (kg/m3) | Void ratio(%) | Obl. angle | Pressure drop (mmHg/m) | Theo. plate(m-1) | Hydraulic diameter (mm) | Liquid load (m3/m2h) | Max. Factorm/s (Kg/m3)-1 |

| 125Y | 125 | 320 | 90 | 45° | 1.8 | 1.8 | 28 | 0.2-100 | 3 |

| 160Y | 160 | 370 | 85 | 45° | 2 | 2 | 15 | 0.2-100 | 2.8 |

| 250Y | 250 | 420 | 80 | 45° | 2 | 2.5 | 12 | 0.2-100 | 2.6 |

| 350Y | 350 | 470 | 78 | 45° | 2.5 | 2.8 | 10 | 0.2-100 | 2.5 |

| 400Y | 400 | 500 | 75 | 45° | 3 | 3 | 8 | 0.2-100 | 2 |

| 450Y | 450 | 520 | 72 | 45° | 4 | 4 | 7 | 0.2-100 | 1.8 |

| 550Y | 550 | 620 | 74 | 45° | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

| 700Y | 700 | 650 | 72 | 45° | 6 | 7 | 5 | 0.15-100 | 1.3 |

| 100X | 100 | 280 | 92 | 30° | 1.5 | 1 | 30 | 0.2-100 | 3.5 |

| 125X | 125 | 300 | 90 | 30° | 1.8 | 1.5 | 28 | 0.2-100 | 3.2 |

| 160X | 160 | 350 | 85 | 30° | 2 | 1.8 | 15 | 0.2-100 | 3 |

| 250X | 250 | 380 | 80 | 30° | 2.5 | 2.3 | 12 | 0.2-100 | 2.8 |

| 350X | 350 | 450 | 78 | 30° | 3 | 2.5 | 10 | 0.2-100 | 2.6 |

| 400X | 400 | 480 | 75 | 30° | 4 | 2.8 | 8 | 0.2-100 | 2.2 |

| 450X | 450 | 500 | 72 | 30° | 4.5 | 3-4 | 7 | 0.2-100 | 2 |

| 470X | 470 | 440 | 75 | 30° | 5 | 5 | 7 | 0.2-100 | 1.8 |

| 550X | 550 | 620 | 74 | 30° | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

| 700X | 700 | 650 | 72 | 30° | 6 | 7 | 5 | 0.15-100 | 1.3 |

| Typical Application | a) Rectifying organic halide. b) Rectifying and absorbing some corrosive mixtures, which are definitely regulated in pressure drop and theoretic plate number. c) Applied in some towers that contain a large quantity of natural media used to absorb nitric acid and concentrated sulfuric acid, as well as for purifying the air in chemical plants. d) Operating in vacuum conditions at a bottom absolute pressure of 100pa. e) Used in heat exchanger and demisting, or as a catalyst carrier. |

||||||||

Benefits

– High capacity. New tower design may reduce diameter, while renovate old towers may increase capacity significantly.

– High separation efficiency. Since it has much larger specific surface area compared to random packing.

– Low pressure drop, which leads to reduce energy consumption largely.

– Large flexibility, and scale effect is not obvious.

– Suitable for all tower diameters.

– Strong resistance to corrosion of acid and alkali, especially to H2S, naphthenic acid and Cl- .

Products

Molecular Sieve

- 4A Molecular Sieve

- 5A Molecular Sieve

- 13X Molecular Sieve

- 13X APG Molecular Sieve

- XH-7 Molecular Sieve

- XH-9 Molecular Sieve

- Insulating Glass Molecular Sieve

- Activated Molecular Sieve

- Carbon Molecular Sieve

- ZSM-5 Series Shape-selective Zeolites

- NaY Absorbent

Activated Alumina

Catalyst

Silica Gel

Activated Carbon

Ceramic Ball

Random Packing

- Ceramic Cross Partition Ring

- Ceramic Cascade Mini Ring

- Ceramic Super Saddles

- Ceramic Pall Ring

- Ceramic Raschig Ring

- Ceramic Baffle Ring

- Ceramic 3Y Ring

- Ceramic Wheel Ring

- Ceramic Intalox Saddles

- Metal Cascade Mini Ring

- Metal Raschig Ring

- Metal Super Raschig Ring

- Metal Inner Arc Ring

- Metal Conjugate Ring

- Metal Super Mini Ring

- Metal Pall Ring

- Metal Super Saddles

- Metal Intalox Saddles

- Plastic Sun Protection Hollow Ball for Reservoirs

- Plastic Snow Flake

- Plastic Liquid Surface Covering Ball

- Q-Pack

- Plastic Conjugate Ring

- Plastic Tri-Pack

- Plastic Heilex Ring

- Plastic Teller Rosette Ring

- Plastic Hollow Floatation Ball

- Plastic Polyhedral Hollow Ball

- Plastic Cascade Mini Ring

- Plastic Super Saddles

- Plastic Intalox Saddles

- Plastic Pall Ring

- Plastic Raschig Ring

- Pentagon Ring

- Plastic VSP

- Plastic Hiflow Ring

- Plastic Angular Ring

Structured Packing

Molecular sieves for medical oxygenators

A measure to prevent infection

Ceramic grate sulfur noodles

Rashig's crimped rings

Prismatic springs

Kaldens

Products

We are up to date with technical innovations and implement them as part of our offer.

%

Satisfaction

Our products are of the highest possible quality. When you buy from us, you buy safely.

Years of experience

We know everything about our products. Practical knowledge acquired through years of presence in the industry.

Countries

Our brand has visited countries all over the world. We deliver products, among others to Germany, Sweden and the United States.

HurtGral - Your supplier of molecular sieves.

Contact

If you want to discuss your order, ask about products or discuss product specifications, please contact us.

Call +48 792 020 580 or use the contact form.

HurtGral - Your supplier of molecular sieves.

Ceramic packing, yeast, enzymes, additives for the food industry.